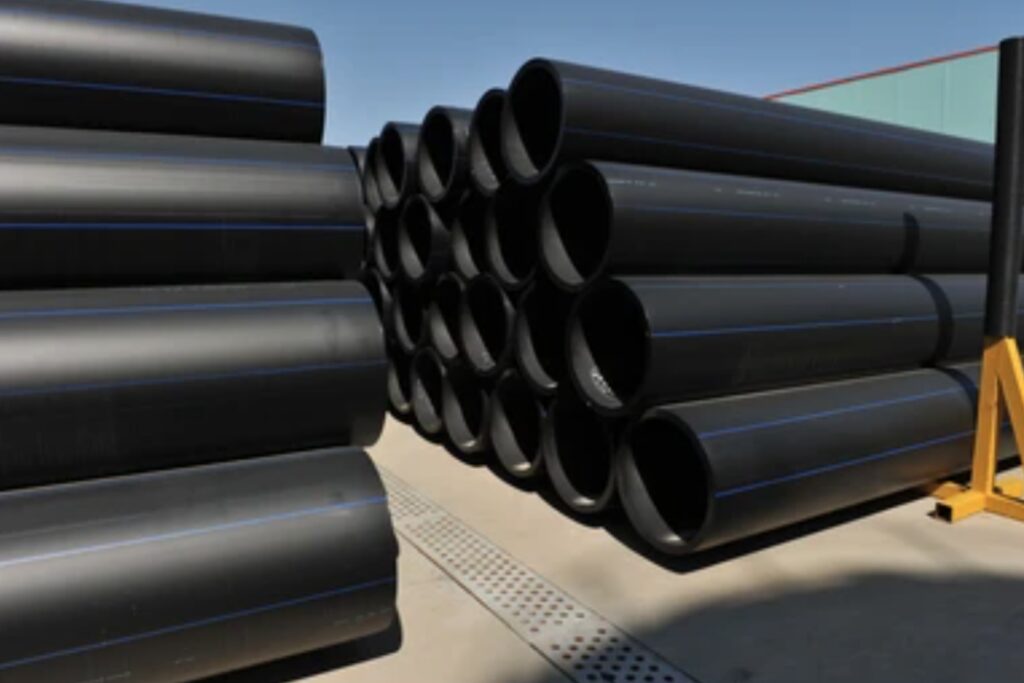

In the realm of plumbing, innovation is constantly pushing the boundaries of what is possible. Among the latest advancements, HDPE (High-Density Polyethylene) pipes have emerged as a game-changer. With their exceptional durability, flexibility, and versatility, HDPE pipes are revolutionizing plumbing systems around the world. Let’s dive into the world of HDPE pipes and explore the fascinating aspects that make them stand out.

- Composition:

HDPE pipes are composed of high-density polyethylene, a thermoplastic polymer known for its outstanding strength and durability. The material is derived from petroleum and ethylene, making it highly resistant to corrosion, chemicals, and weathering.

- Construction:

HDPE pipes are manufactured using a process called extrusion. During extrusion, the polyethylene material is melted and forced through a die, resulting in a seamless pipe with a consistent diameter and thickness. The flexibility of HDPE pipes allows for coiling during production, enabling the creation of long, continuous pipelines without the need for additional joints.

Advantages of HDPE Pipes: Redefining Plumbing Systems

- Exceptional Durability:

HDPE pipes boast impressive durability, capable of withstanding extreme temperatures, pressure, and external forces. Their high impact resistance and flexibility prevent cracking, ensuring long-lasting performance and reducing the need for frequent repairs or replacements.

- Corrosion and Chemical Resistance:

Unlike traditional piping materials like metal or concrete, HDPE pipes are highly resistant to corrosion caused by chemicals, acids, and even sewage. This resistance makes them ideal for various applications, including industrial settings, wastewater management, and underground installations.

- Leak-Free Joints:

HDPE pipes employ heat fusion techniques to create leak-free joints. By heating the pipe ends and fusing them together, a monolithic system is formed, eliminating the risk of leaks and ensuring a reliable plumbing network.

- Flexibility for Easy Installation:

The flexibility of HDPE pipes simplifies the installation process. Their ability to bend and adapt to the terrain reduces the need for extensive excavation and allows for faster, more cost-effective installations. The lightweight nature of HDPE pipes further aids in handling and transportation.

- Environmental Sustainability:

HDPE pipes are environmentally friendly, as they are 100% recyclable. Their long lifespan, coupled with their ability to be repurposed and recycled, minimizes waste and contributes to sustainable plumbing practices.

Applications of HDPE Pipes: Versatility at Its Finest

- Water Supply and Distribution:

HDPE pipes are widely used for water supply and distribution systems, including municipal water networks, agricultural irrigation, and residential plumbing. Their resistance to corrosion, chemicals, and weathering ensures clean and safe water delivery.

- Gas Distribution:

Due to their exceptional strength and leak-free joints, HDPE pipes are an excellent choice for natural gas and propane distribution. Their resistance to harsh underground conditions and low permeability make them a reliable option for gas transmission.

- Industrial Applications:

HDPE pipes find extensive use in various industrial applications, such as mining, chemical processing, and wastewater treatment. Their resistance to chemicals and high durability make them suitable for transporting corrosive fluids and handling demanding conditions.

The Future of Plumbing: HDPE Pipes Leading the Way

In an era of constant technological advancement, plumbing systems are evolving to meet the growing demands of efficiency, durability, and sustainability. HDPE (High-Density Polyethylene) pipes have emerged as a frontrunner in this transformation, heralding a new era for the plumbing industry. This article unravels the potential of HDPE pipes and how they are leading the way towards a future of advanced plumbing systems.